Call Us

(877) 355-6528

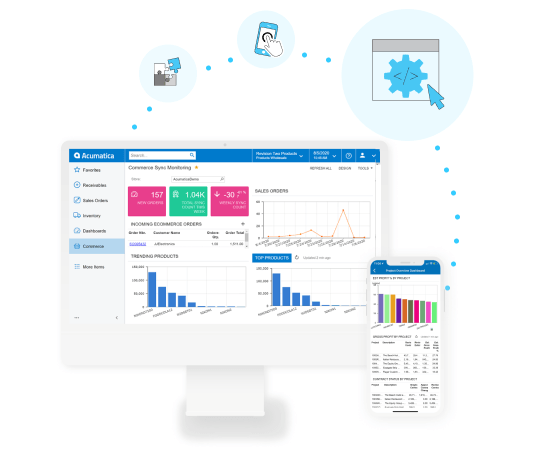

Aqurus delivers Acumatica Cloud ERP, purpose-built for discrete manufacturers in Canada. With real-time visibility, automated workflows, and powerful reporting, you’ll gain total control over your operations — from the shop floor to finance. Scale confidently with flexible, user-friendly tools designed to grow with your business.

Unify inventory, production, finance, and reporting in one cloud-based ERP system

Automate BOMs, routing, and scheduling to streamline manufacturing processes

Track real-time material costs, labour, and margins to improve profitability

Ensure compliance with built-in quality controls and audit-ready reporting

Enable remote teams with mobile access and role-based dashboards

Avoid per-user fees and scale freely with flexible licensing

Let’s Explore How ERP Can Simplify Your Operations

What You Can Do with Acumatica Manufacturing ERP

ERP Solutions for Every Type of Manufacturer

Guides, Tools, and Case Studies for ERP Evaluation and Implementation

Manufacturing ERP Modules and Features in Acumatica

Envent Engineering, a top sulfur analyzer manufacturer for the oil and gas industry, skyrocketed growth by 4X after implementing Acumatica Manufacturing ERP. Struggling with outdated systems, Envent teamed up with Aqurus Solutions to modernize operations. The outcome: real-time data access, improved visibility, and streamlined processes fueling rapid expansion.

Key Benefits Envent Experienced:

→ Teams spend hours reconciling disconnected spreadsheet data

→ Errors and delays make accurate reporting nearly impossible

→ Leaders lack timely visibility into financial performance

→ Business growth slows without one connected platform

→ Stockouts stop production and create late order deliveries

→ Overstock ties up valuable working capital unnecessarily

→ Balancing supply and demand is difficult without real-time data

→ Customer confidence drops when delays or shortages occur

→ Audits and inspections take longer without automation tools

→ Manual entries increase the risk of human errors in records

→ Compliance becomes harder as industry rules keep evolving

→ Mistakes and oversights can result in higher business costs

→ Labour, material, and overhead costs continue to rise quickly

→ Hidden profit leaks remain unnoticed without real-time data

→ Margins shrink before leaders can identify the problems

→ Missed savings opportunities weaken competitiveness overall

It doesn't have to be this hard

Disconnected systems, rising costs, and compliance headaches are challenges every manufacturer knows too well. The good news: each of these problems has a clear solution. Scroll down to see how one connected platform helps you move past the pain and into control.

Acumatica brings everything together in one connected system-so you can stop chasing information, start making confident decisions, and finally run your manufacturing business with the visibility and control you've been missing.

→ Track inventory, production, and costs with real-time accuracy

→ Improve demand forecasting to reduce errors and blind spots

→ Automate purchasing to prevent supply delays and shortages

→ Prevent costly stockouts or excess stock holding cash flow

→ Prevent production delays caused by sudden material stockouts

→ Avoid overstock situations that restrict working capital

→ Balance supply and demand with accurate live reporting

→ Deliver on time to maintain customer satisfaction levels

→ Automate safety checks, compliance reports, and certifications

→ Track every step from raw goods to finished product delivery

→ Maintain clean and reliable audit-ready records at all times

→ Reduce compliance mistakes that create costly disruptions

→ Identify hidden costs and inefficiencies before they escalate

→ Reduce production waste and improve process efficiency

→ Protect margins against rising labour and material costs

→ Prevent small cost issues from damaging overall profits

Manufacturing processes vary by industry, products, raw materials, and customer needs. Acumatica supports multiple modes so manufacturers can operate more efficiently and adapt to changing demand.

Quote and track custom jobs with detailed cost visibility to improve profitability.

Streamline high-volume production with standard processes, schedules, and efficiency tracking.

Build finished products quickly from stocked components to meet customer demand on time.

Produce goods only when orders are received, minimizing excess inventory and cash tied up in stock.

Design and build unique products to exact customer specifications while managing costs and schedules.

Offer flexible product options and variations while keeping control over costs and delivery timelines.

Manufacture goods for inventory and fulfill customer orders faster from on-hand stock.

Track and control formulas, recipes, and batches for consistent product quality and compliance.

Manage projects, resources, and costs with integrated visibility into timelines and budgets.

Combine multiple production methods in one system for maximum flexibility and efficiency.

Track costs, measure performance, and manage exceptions with real-time reporting tools built for manufacturers.

Analyze actual vs. estimated job costs to improve accuracy and protect margins.

Monitor WIP in real time to keep production flowing and avoid bottlenecks or missed deadlines.

Give every team member the insights they need with dashboards tailored to their role.

Quickly drill into live data to answer production, financial, and operational questions.

Stay informed with automated alerts that flag issues before they become costly problems.

Create and share custom reports without IT support, using easy, no-code reporting tools.

Acumatica connects engineering and manufacturing to streamline design-to-manufacturing (D2M) processes for new product introductions, item revisions, and approvals. Integrated tools help reduce delays, cut errors, and speed time to market.

Manage design revisions with approval workflows that keep production accurate and up to date.

Integrate directly with PLM and CAD applications to sync product data and reduce rework.

Offer customizable product options while maintaining cost control and production accuracy.

Track complex assemblies, formulas, or recipes with clear BOM structures that fit your production needs.

Quickly compare costs across different batch sizes or production runs to optimize pricing and efficiency.

Optimize throughput and resource utilization with time-phased material planning and finite capacity scheduling tools.

Get a high-level view of production capacity to align resources with demand before issues arise.

Plan production runs in advance to balance inventory, resources, and customer delivery dates.

Ensure the right materials are available at the right time to prevent stockouts and delays.

Match production schedules with actual resource availability to avoid bottlenecks and overtime costs.

Fine-tune operations with detailed scheduling tools that optimize throughput and improve efficiency.

Configure doors, windows, stairs, and other products.

Track serial numbers and time-phase materials with production schedules.

Manage machine setup and scrap with estimates and WIP.

Harmonize bills of materials from CAD or PLM design applications.

Manage production for paper, plastic, automotive, and other industries.

Gain complete control over your manufacturing processes with Acumatica’s powerful BOM and Routing module. Easily manage inventory, production costs, and engineering changes with full revision control and real-time visibility into both financial and engineering views of your product structure. Key capabilities include multi-level visual BOMs, production steps, where-used tracking, phantoms, reference designators, and flexible copy and mass change tools. With built-in cost rollups, multi-site support, and optional engineering change control, you can streamline operations, maintain accuracy, and accelerate time to market.

Simplify financial management across multiple entities with Acumatica’s Intercompany Accounting. Automate transactions, streamline reporting, and reduce errors in consolidated financial statements. Key features include account-based controls, cross-company sales, asset transfers, and account allocations. With support for different financial calendars, company-specific bank accounts, and user access restrictions, you can ensure accurate, secure, and efficient multi-entity operations.

Ensure you have the right materials at the right time with Acumatica’s Material Requirements Planning. This powerful planning tool generates time-phased manufacturing and purchasing plans based on real customer demand and forecasts. Key features include forecasting, MRP detail views, a bucketless system for greater flexibility, and multi-site and multi-warehouse support. With tools to manage lead times, transfers, blanket sales orders, order quantities, and supply by exception, you can streamline procurement, reduce stockouts, and improve production efficiency—all backed by full MRP history and audit trails.

Gain real-time financial insights, accelerate month-end closings, and ensure continuous compliance with a complete set of financial tools. This powerful module supports everything from GL, AP/AR, and cash management to multi-entity accounting, tax and currency management, recurring revenue, payroll, fixed assets, and more. With built-in reporting, mobile access, and global financial capabilities, you can confidently manage complex finances across your organization.

Take full control of your manufacturing process with powerful tools to manage, schedule, and track production orders from start to finish. Monitor material and labour costs in real time, and compare planned, standard, and actual production costs to improve accuracy and profitability. Key capabilities include critical materials planning, backflushing, lot and serial tracking, barcode integration, production dashboards, and multi-site support. With built-in audit trails, cost controls, and optional quality management, you’ll gain the visibility and flexibility needed to optimize shop floor operations and prevent costly errors.

Easily manage budgeting, inventory, change orders, timesheets, billing, profitability, and reporting for each project—while keeping everything integrated with your company-wide financials. With multi-currency support and full visibility, this module includes powerful tools like project cross tracking, advanced billing, time and expense management, and seamless connections to GL, AP, sales and purchase orders, and inventory.

Capture real-time shop floor activity with Acumatica’s Manufacturing Data Collection module. Using barcode scanning and mobile devices, workers can track material movement and clock in and out of production tasks—automatically updating inventory and work in process (WIP). Compatible with both personal smartphones and rugged warehouse scanners, the system reduces data entry errors and eliminates delays from manual updates. Live dashboards and push notifications give supervisors immediate visibility into labour and material usage, improving accuracy, accountability, and responsiveness across the production floor.

Optimize your production operations with Advanced Planning and Scheduling (APS) tools that help you reduce bottlenecks, maximize resource utilization, and deliver on time. This powerful module gives manufacturers real-time visibility into material availability, labour capacity, and machine schedules—ensuring accurate, constraint-based planning. Seamlessly integrated with Acumatica’s MRP engine, APS supports both finite and infinite capacity scheduling, enabling smarter decisions based on actual shop floor data. Visual scheduling boards, dispatch lists, and Capable-to-Promise (CTP) functionality provide planners and sales teams with the tools to commit to realistic delivery dates, align resources, and respond faster to changes in demand—all while keeping production efficient and customer expectations on track.

Take control of your inventory with flexible, intelligent tools that simplify item management, automate replenishment, and ensure full traceability across all warehouse locations. Acumatica’s Inventory Management module supports advanced features like matrix items, kitting and disassembly, and lot and serial tracking—so you can manage complex inventory with ease. Automatically balance supply and demand using powerful replenishment logic based on safety stock, lead times, and seasonal demand. Integrated with purchasing, sales, manufacturing, and financials, this module helps reduce carrying costs, avoid stock-outs, and improve inventory accuracy with barcode scanning, cycle counts, and real-time visibility—empowering your team to move faster, reduce waste, and operate with confidence.

Streamline procurement and strengthen vendor relationships with Purchase Order Management tools that automate buying, reduce costs, and connect every part of your business. This module simplifies the entire purchasing process—from vendor quote to payment—while supporting drop shipments, blanket orders, and landed cost tracking. Automatically generate purchase orders based on stock levels, economic order quantities, or sales demand, and choose the best vendor based on pricing or lead times. Integrated with inventory, sales, projects, and accounts payable, this module provides complete visibility and control over purchasing activities. With approval workflows, cross-company transactions, and role-based dashboards, your team can manage supply chain complexity with accuracy, speed, and confidence.

Streamline custom manufacturing with a rules-based Product Configurator that lets you create configurable items with ease—directly from quotes, sales orders, or production orders. Define item attributes like size, style, and colour, and use formulas to calculate component quantities, material costs, and final pricing in real time. Each configuration automatically generates a unique bill of material and routing, ensuring accuracy from quote to delivery. Support both configure-to-order and configure-to-stock workflows, reuse past configurations, and apply dependencies between features to prevent errors. With seamless integration across CRM, inventory, and production, this module simplifies complex product setup while improving speed, consistency, and customer satisfaction.

Boost warehouse efficiency with Acumatica’s Warehouse Management System, built to streamline fulfilment through barcode scanning, mobile apps, and paperless picking. Automate key tasks like receiving, put-away, picking, packing, and physical inventory to reduce errors and speed up operations. With support for wave and batch picking, shipping carrier integration, and role-based dashboards, you get full visibility into warehouse activities in real time. Seamless integration with inventory, sales, purchasing, and production ensures smooth coordination across your entire supply chain.

Simplify your quote-to-cash process with Sales Order Management tools that give your team real-time access to inventory, pricing, and order status. Automatically generate orders from quotes, apply flexible discounts and pricing rules, and fulfil from multiple warehouses with partial or consolidated shipments. Boost customer satisfaction with up-sell and cross-sell suggestions, configurable delivery schedules, and drop shipment support. With full integration across inventory, purchasing, CRM, and accounts receivable, this module helps streamline fulfilment, reduce errors, and improve visibility at every stage of the sales cycle.

Keep field operations connected and running smoothly with Acumatica’s Field Service Management module. Schedule the right technician at the right time using skill, location, and availability, and track appointments in real time with GPS and mobile updates. Technicians can access job details, capture signatures, and process payments directly from the field. Integrated with inventory, purchasing, CRM, and project management, this module helps you manage contracts, track service history, and ensure your team has the tools, parts, and information they need—whether delivering, repairing, or installing on-site.

Take control of product changes with Acumatica’s Engineering Change Control module. Manage version updates to bills of material and routings with full audit tracking, automated approvals, and clear visibility into requested and approved changes. Combine multiple engineering change requests into a single order, compare BOM revisions side-by-side, and shorten design cycles using the interactive Engineering Workbench. With built-in workflows and security controls, ECC ensures your team stays aligned on changes—reducing errors and improving collaboration across engineering, production, and planning.

Build fast, accurate quotes with Acumatica’s Manufacturing Estimating module. Create estimates for custom or new items not yet in inventory, define labour, material, tooling, and overhead costs, and apply flexible markups to calculate final pricing. Estimates can be built from scratch, copied from prior jobs, or generated from connected PLM or CAD tools. Once approved, quotes can be converted into inventory items, sales orders, or production orders. Integrated with CRM and supported by dashboards and estimate accuracy reports, this module helps manufacturers win more business and streamline make-to-order workflows.

Manage every step of the order process with Acumatica’s Order Management module. Handle sales of stock and non-stock items, automate purchase requisitions and approvals, and link sales and purchase orders to streamline fulfilment. Built-in CRM integration helps you convert quotes into orders without duplicate entry, while flexible pricing, discounting, and up-sell features boost revenue. Whether selling digital products, services, or physical inventory, this module provides a clear, connected view of your supply chain—so you can serve customers faster and manage vendors with confidence.

Run your retail and eCommerce business from one connected system with Acumatica Retail Edition. Manage in-store and online orders, inventory, fulfilment, and returns with real-time visibility and automated workflows. Native integrations with Shopify, BigCommerce, and POS systems keep sales channels in sync, while tools like matrix items, flexible product types, and drop-shipping options support a seamless customer experience. With built-in financials, CRM, and reporting, you can reduce errors, improve efficiency, and scale your operations—all while delivering consistent service across every channel.

(877) 355-6528

info@aqurus.ca

Start Your Chat